At Wako Seiki, we are producing with an attention to detail that accounts for each and every work process and part, and have a strong awareness of the operational stability of our parts and the stability of the supply.

In order to carefully check each production process and conditions of the completed parts, we even provide retroactive inspection into the cause of damages or defect for each part, offering the most appropriate support.

| Part name | Image | Details about company use |

|---|---|---|

| Case body |  |

Shake-resistant, dust-proof, oil-proof design due to full aluminum die cast body *For 5-digit specifications, push-in indentation to increase shake-resistance <Numbering hold part> |

| Wiring cable |  |

Support for safety standards Cold-proof/oil-proof specifications (Mitsuboshi 300V soft vinyl cabtire VCT,600V soft vinyl cabtire SVCT) |

| Numbering |  |

Sharpened and fired with aluminum NC With durability and shake-resistance, support against material cracking in cold locations and expansion from sudden changes in temperature |

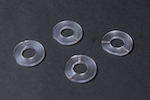

| Set ring |  |

Polyester plastic processing (Thanroid PET Ace) Not easily influenced from outside changes in temperature due to being same material as PET bottles Support for printing numbering |

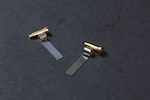

| Set method |  |

Enameled screws (2mm) Numeric values set through tightening Excellent level of endurance due to implementation of (ON/OFF) micro switch toggle |

| Gear-related |  |

Both input shafts and master cogs are individually crafted with care by engineers,making it possible to manufacture gears for a variety of rotation ratios. |

| Micro switch |  |

Omron V-15-1E6 AC250V-15A |

| Actuator |  |

Internal press machine part, used in over-the-shelf products by every micro switch maker Uses independently designed and produced parts with durability and shake-resistance since use for long periods can cause defects in durability |

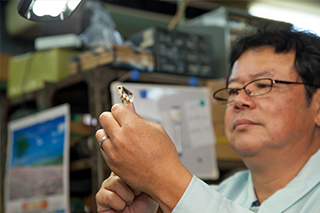

| Assembly process |  |

Excellent endurance and shake-resistance through assembly that takes into account fine adjustments of each scope of measurement (using our own standards) in dealing with the operating conditions of the micro switch and each component in the assembly process |